It is good, but:

When curing, 7/10 times when the plate starts rotating, it starts with a stronger rotation and sometimes it can move the figures enough that they fall off the plate.

When I turn the timer softly it almost always goes back 1 interval. When I turn it fast there are no issues.

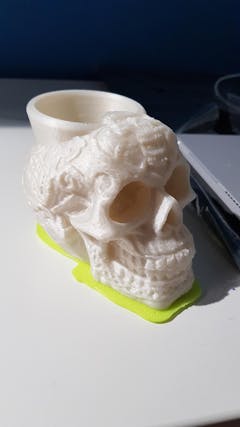

A bit more brittle than I expected, but still a very good product

Uitstekend tensioner mooie afwikkeling